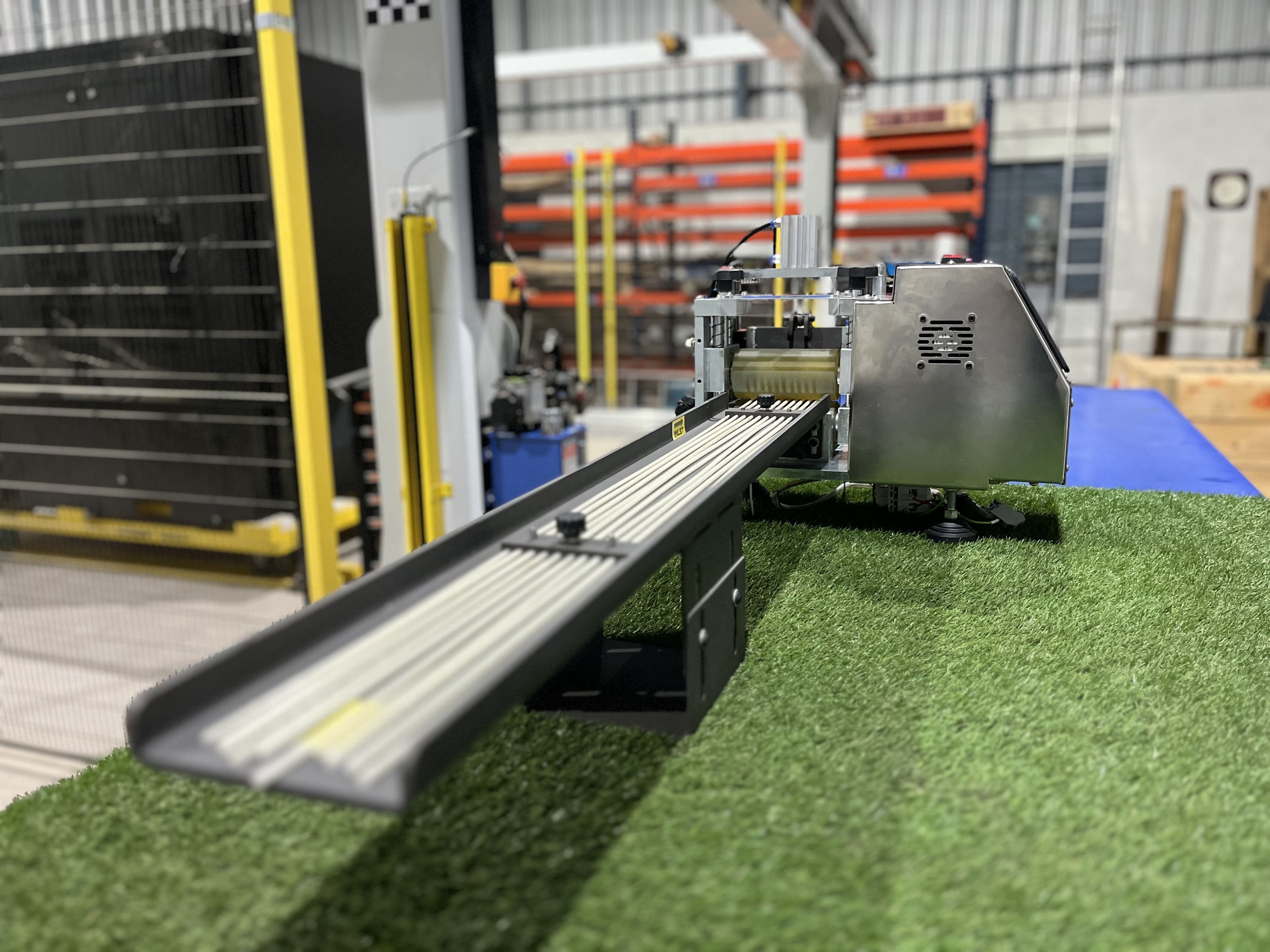

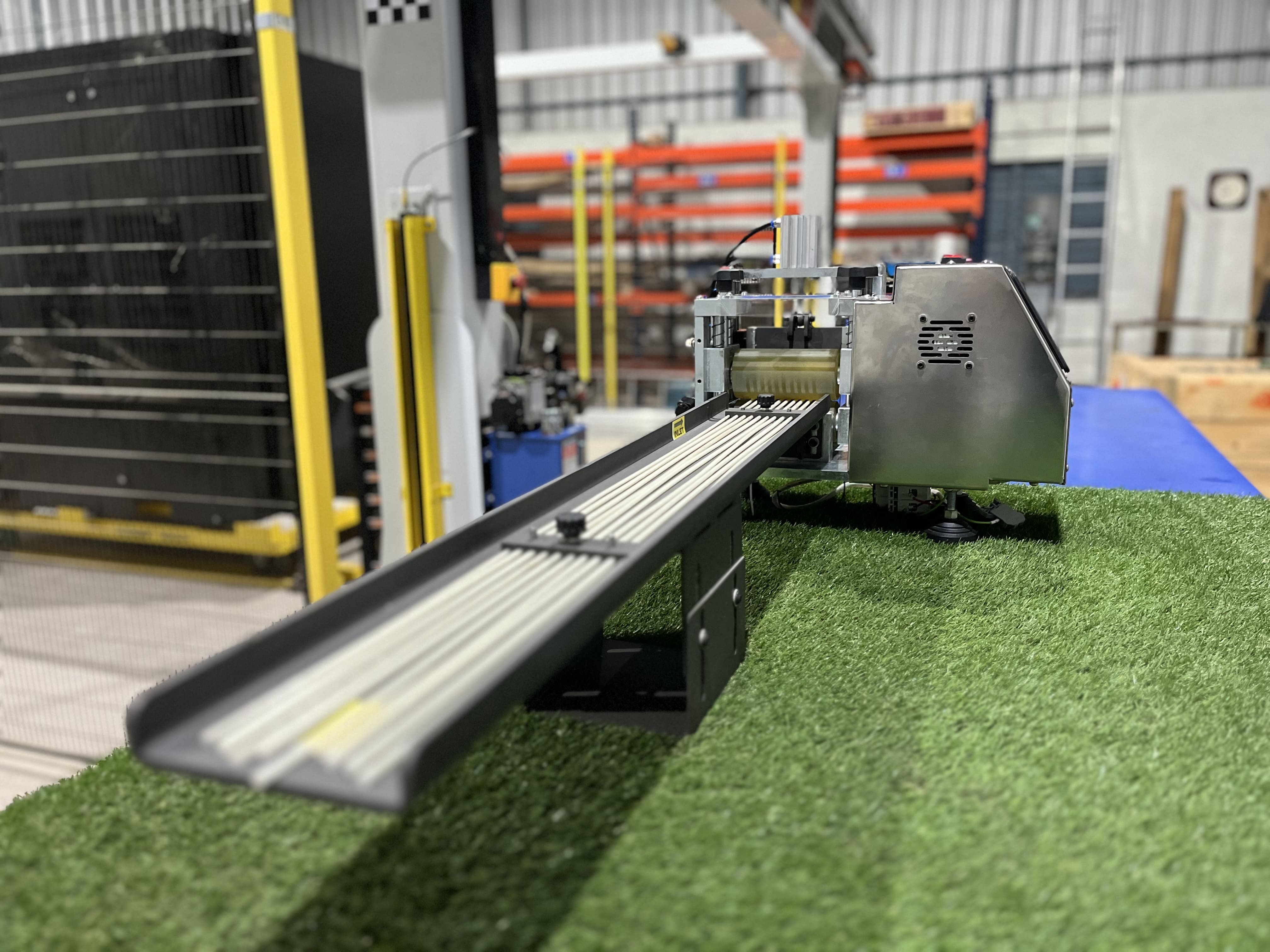

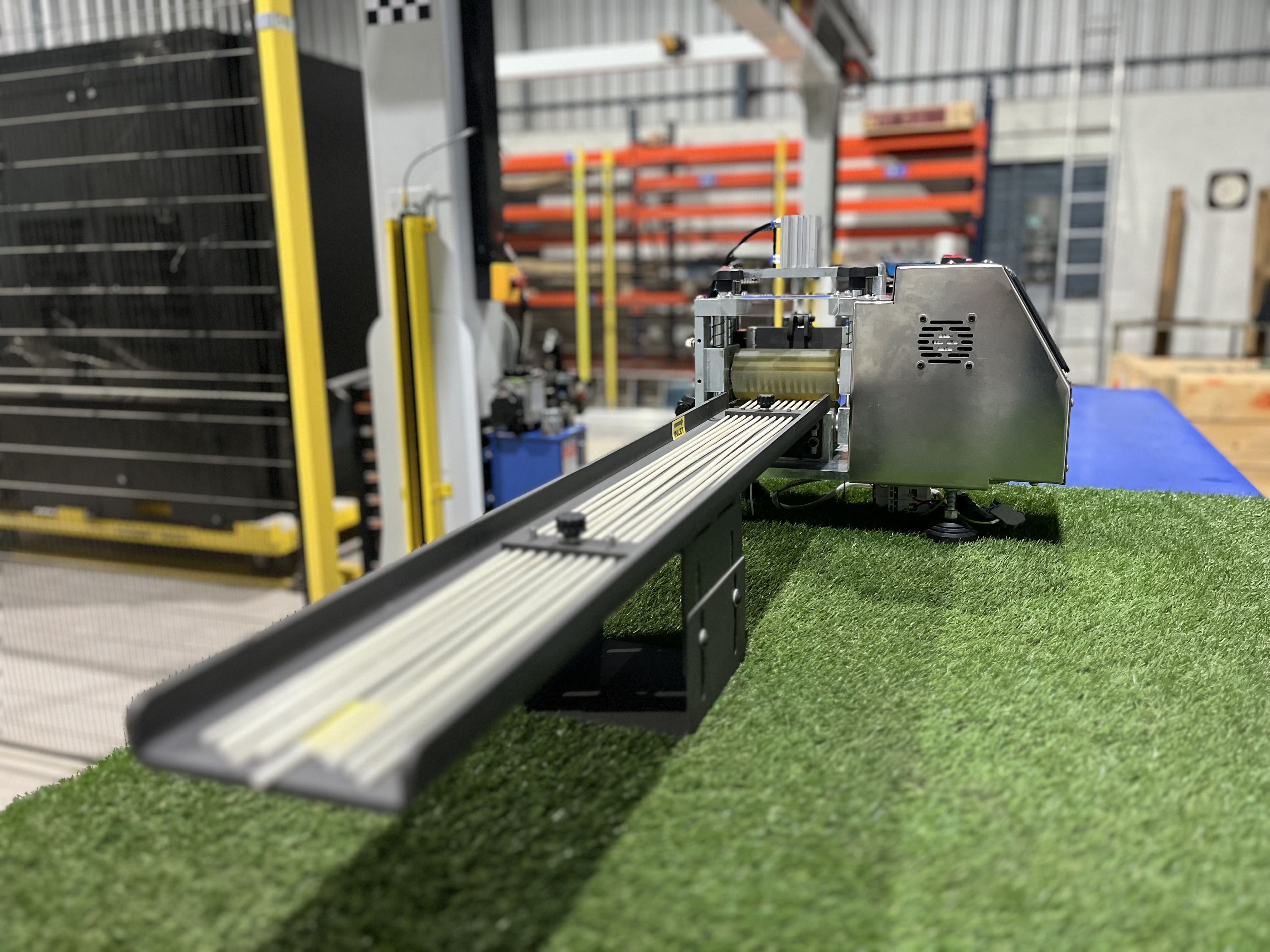

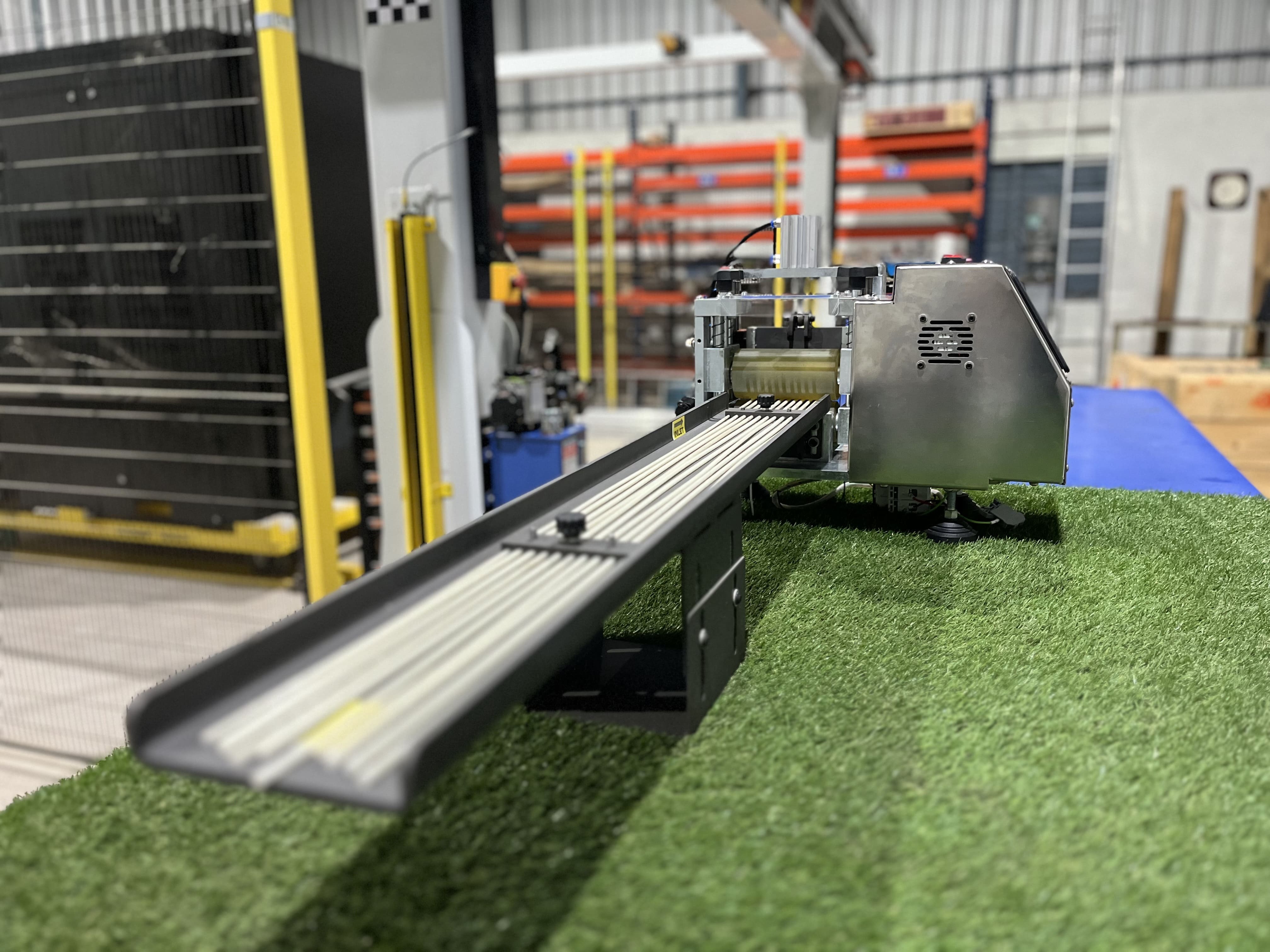

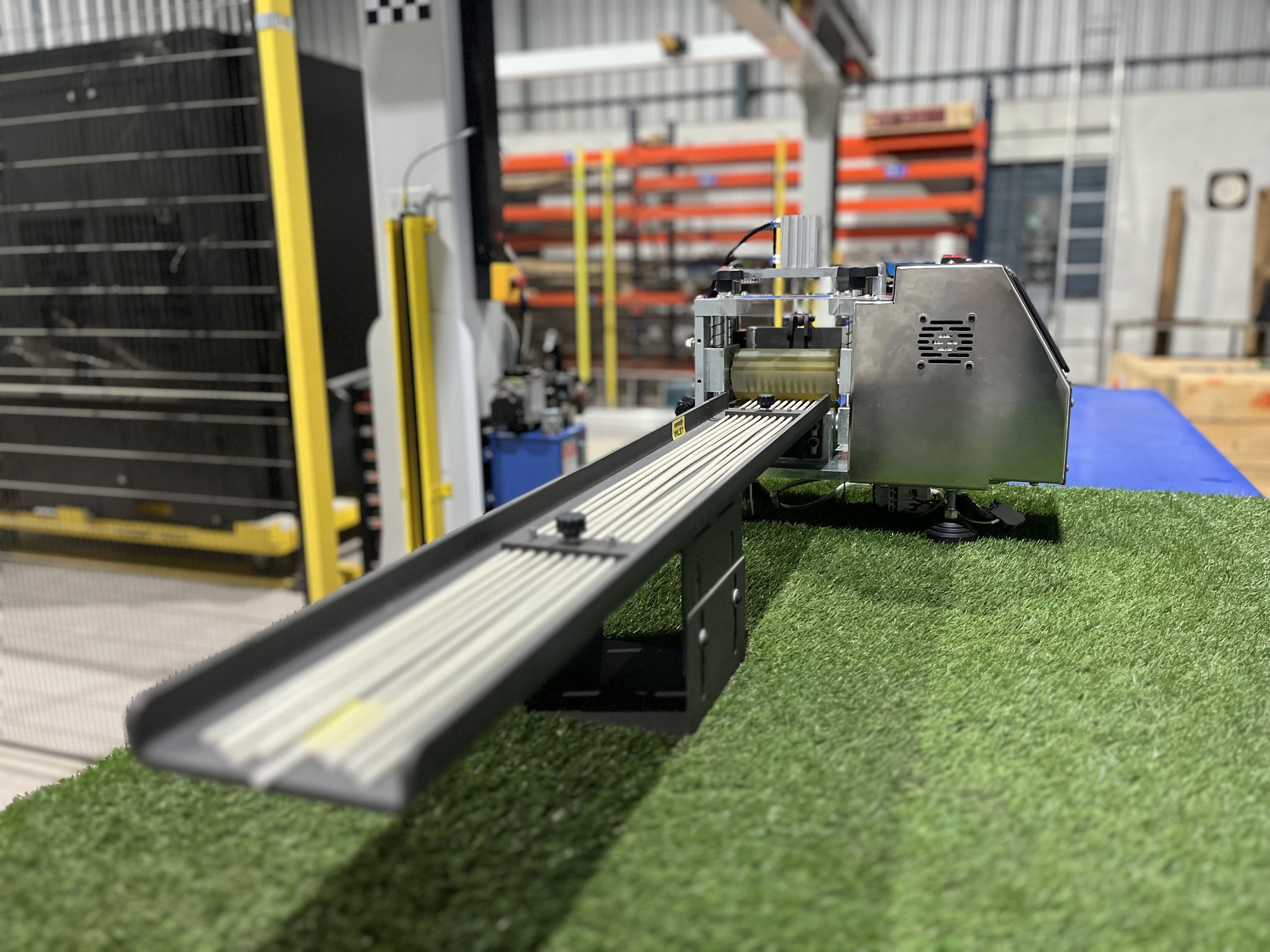

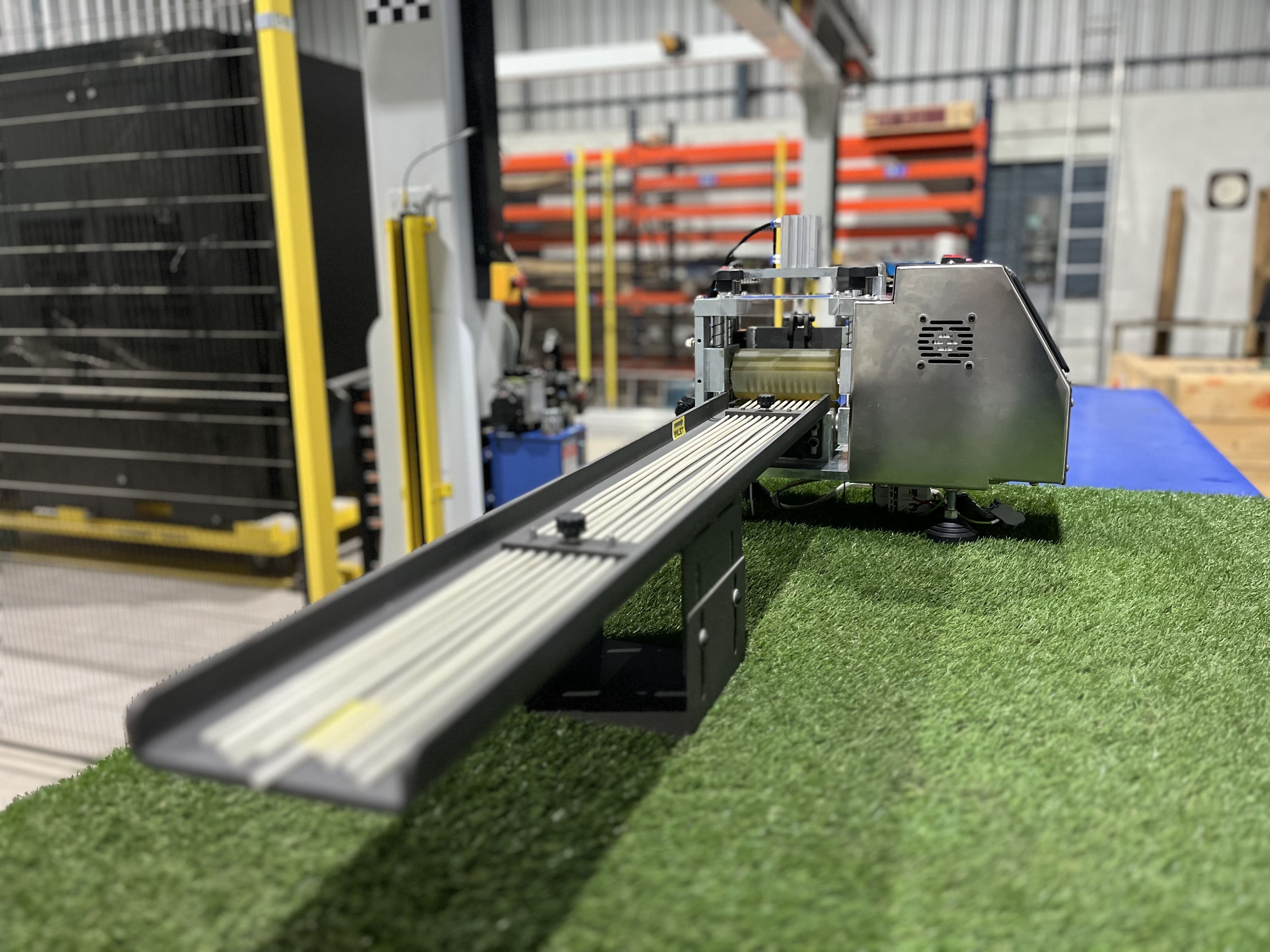

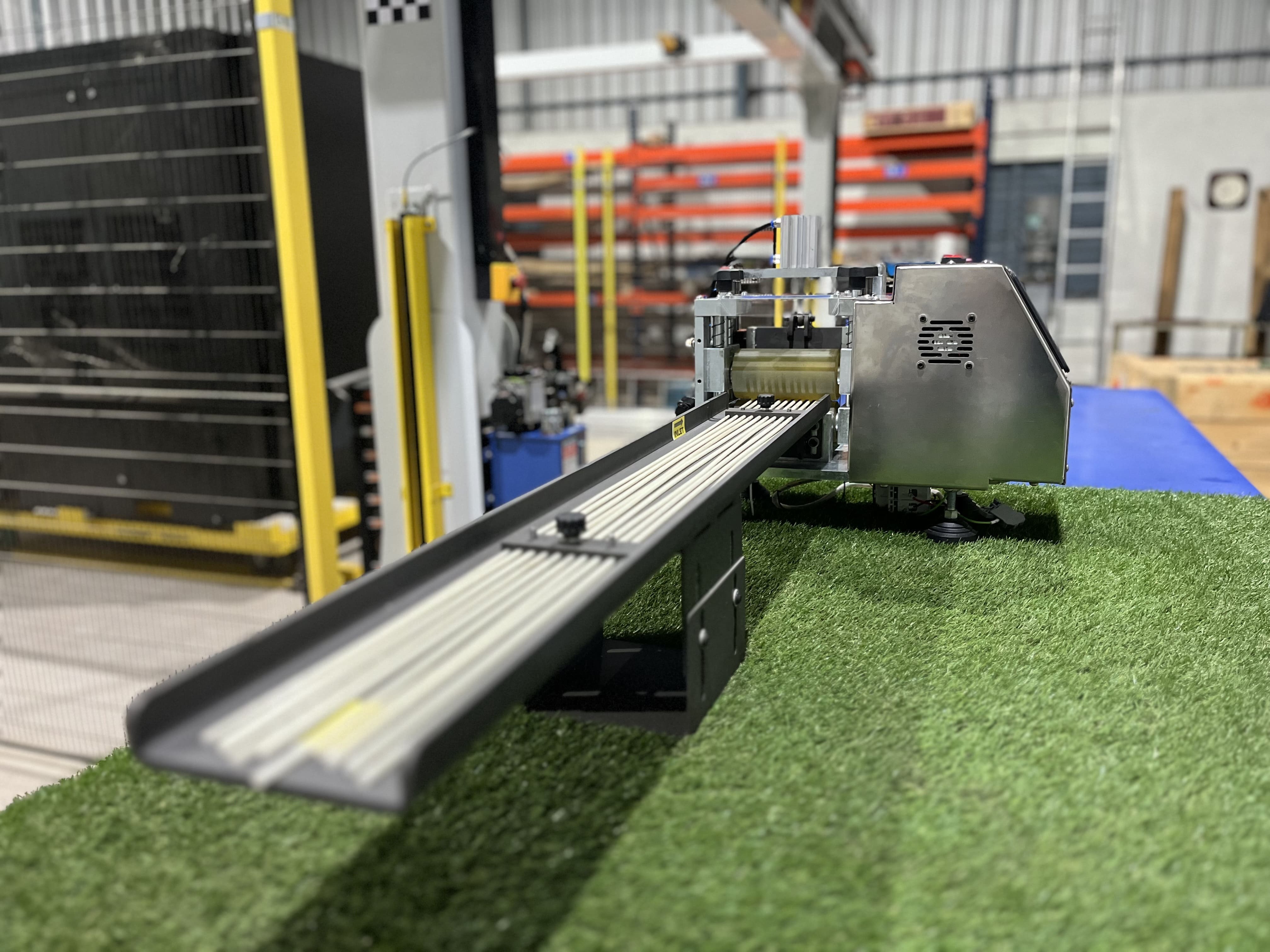

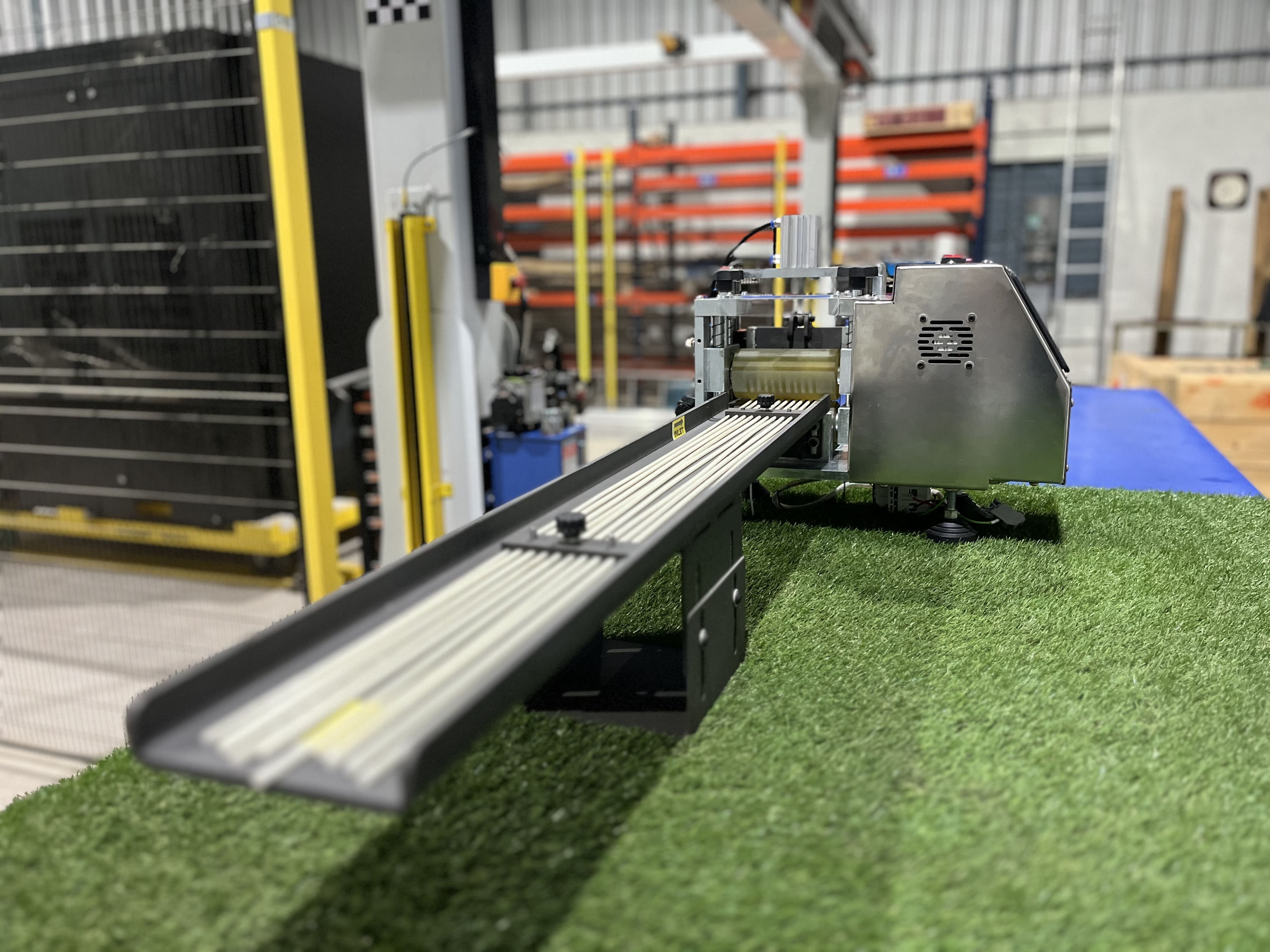

Sleeve cutting machine

Price 310000 INR/ Number

Sleeve cutting machine Specification

- Attributes

- Strong, Durable, Easy To Operate, Consume Less Power

Sleeve cutting machine Trade Information

- Minimum Order Quantity

- 1 Number

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Sleeve cutting machine

A motor coil sleeve cutting machine is a specific type of equipment used in the manufacturing or repair of electric motors. It's designed to cut sleeves or insulation materials used in the winding of motor coils to precise dimensions. Here's a description of the typical features and components you might find in such a machine:

-

Frame and Structure: The machine typically has a sturdy frame or chassis to support its components. It's designed to withstand the rigors of industrial use and provide stability during operation.

-

Cutting Mechanism: The cutting mechanism is the central part of the machine. It may use various methods to cut motor coil sleeves, including rotary blades, straight blades, or specialized cutting tools designed for specific materials like insulation paper or tape.

-

Control System: Like other industrial machinery, a motor coil sleeve cutting machine may incorporate a computerized control system. This system allows operators to input parameters such as the length, width, and thickness of the sleeves to be cut. It coordinates the movement of the cutting mechanism to ensure precise cuts according to these specifications.

-

Safety Features: Safety is paramount in industrial settings. These machines often include features such as emergency stop buttons, safety guards, and sensors to prevent accidents and protect operators during operation.

-

Feed Mechanism: The machine needs a mechanism to feed the material consistently and accurately into the cutting area. Depending on the design, this may involve manual feeding by operators or automated feeding mechanisms such as rollers or belts.

-

Adjustability: Motor coil sleeve cutting machines often offer adjustable settings to accommodate different materials, thicknesses, and cutting requirements. This versatility allows for customization and ensures optimal results for various types of motor coils.

-

Maintenance and Servicing: Regular maintenance is essential to keep the machine in optimal working condition. This may involve routine cleaning, lubrication of moving parts, and occasional repairs or replacements of worn components.

-

Material Handling: Some machines may include features for handling materials before and after cutting, such as material feeding trays, collection bins, or conveyor systems.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

GST : 33AARFD1027H1ZO

|

|

DSI Industrial Automation and Machineries

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry