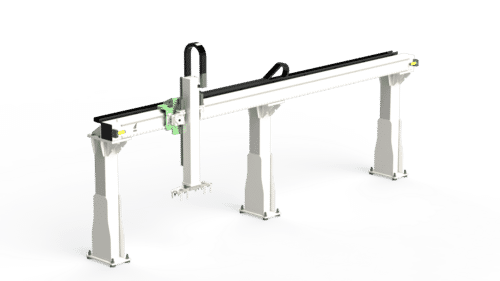

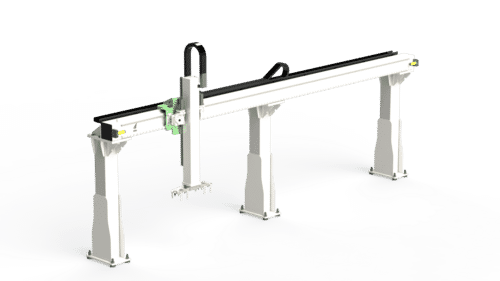

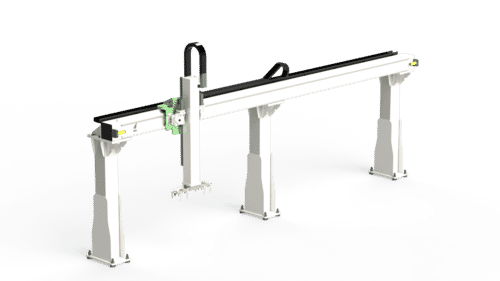

3 Axis Gantry robot for tyre industry

Price 1400000 INR/ Unit

3 Axis Gantry robot for tyre industry Specification

- Usage

- Industrial

- Condition

- New

- Size

- Different Sizes Available

- Power Source

- Electric

- Color

- White

- Attributes

- Strong, Durable, Easy To Operate

3 Axis Gantry robot for tyre industry Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID)

- Delivery Time

- 10-15 Days

- Main Domestic Market

- All India

About 3 Axis Gantry robot for tyre industry

Gantry robots are essential components of tire manufacturingfacilities, where they contribute to improving productivity, quality, andsafety across different stages of the production process. With their precision,speed, and versatility, gantry robots optimize tire manufacturing operations,streamline material handling, and ensure consistent product quality.

In the tire industry, gantry robots are deployed in thefollowing key applications:

Tire Building: Gantry robots are used in tire buildingprocesses, where they handle tire components such as beads, carcasses, belts,and treads. They precisely position and assemble these components ontotire-building drums, ensuring uniformity and accuracy in the tire constructionprocess.

Tire Inspection: Gantry robots equipped with advanced visionsystems and sensors are employed for tire inspection tasks. They inspect tiresfor defects, irregularities, and dimensional accuracy, facilitating earlydetection of quality issues and ensuring compliance with stringentmanufacturing standards.

Material Handling: Gantry robots play a crucial role inmaterial handling tasks within tire manufacturing facilities. They transportraw materials, semi-finished products, and finished tires between workstations,storage areas, and conveyors, optimizing production flow and minimizing manuallabor.

Quality Control and Sorting: Gantry robots are integratedinto quality control and sorting processes to ensure the consistency anduniformity of tire products. They sort tires based on predetermined criteriasuch as size, tread pattern, and quality parameters, facilitating efficientdownstream operations and reducing waste.

Palletizing and Packaging: Gantry robots are employed for palletizingfinished tires and packaging them for shipping and distribution. They optimizepallet loading patterns, stack tires efficiently, and ensure secure packagingto prevent damage during transit, thereby enhancing warehouse efficiency andcustomer satisfaction.

Tire Testing: Gantry robots assist in tire testing processes,where they position tires on test rigs and perform dynamic testing proceduressuch as endurance testing, rolling resistance testing, and noise testing. Theyautomate these testing operations, improve testing accuracy, and accelerateproduct development cycles.

End-of-Line Automation: Gantry robots are integrated intoend-of-line processes for tire inspection, labeling, and sorting before finalpackaging. They streamline these processes, reduce labor costs, and improvethroughput, enabling tire manufacturers to meet the demands of high-volumeproduction and distribution.es of a dynamic and competitive market.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gantry Robot System Category

2 Axis Gantry Robot

Price 700000 INR / Number

Minimum Order Quantity : 1 Number

Condition : New

Color : White

Usage : Industrial

Power Source : Electric

DSI - Pick and Place Gantry Robot

Price 900000 INR / Number

Minimum Order Quantity : 1 Number

Condition : New

Color : White

Usage : Industrial

Power Source : Electric

3 Axis Gantry robot for Automobile industry

Price 1200000 INR / Number

Minimum Order Quantity : 1 Unit

Condition : New

Color : White

Usage : Industrial

Power Source : Electric

3 Axis Gantry robot for food industry

Price 900000 INR / Number

Minimum Order Quantity : 1 Number

Condition : New

Color : White

Usage : Industrial

Power Source : Electric

GST : 33AARFD1027H1ZO

|

|

DSI Industrial Automation and Machineries

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry