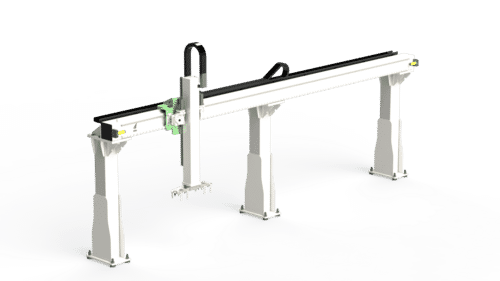

3 Axis Gantry robot for food industry

Price 900000 INR/ Number

3 Axis Gantry robot for food industry Specification

- Usage

- Industrial

- Condition

- New

- Size

- Different Sizes Available

- Power Source

- Electric

- Color

- White

3 Axis Gantry robot for food industry Trade Information

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 1 Number Per Month

- Delivery Time

- 45 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About 3 Axis Gantry robot for food industry

Gantry robots are becoming indispensable assets in varioussegments of the food industry, ranging from food processing and packaging towarehousing and distribution. With their precision, speed, and hygienecompliance, gantry robots address the unique challenges faced by foodmanufacturers and processors, contributing to improved productivity, productconsistency, and compliance with stringent food safety regulations.

In the food industry, gantry robots are deployed in diverseapplications such as:

Packaging Automation: Gantry robots play a crucial role inautomating packaging processes for a wide range of food products, includingsnacks, baked goods, frozen foods, and beverages. They efficiently handleproduct loading, grouping, sorting, and packaging, ensuring uniformity,accuracy, and compliance with packaging standards.

Palletizing and Depalletizing: Gantry robots excel inpalletizing finished products and depalletizing raw materials or packagingmaterials in food manufacturing and distribution facilities. They optimizepallet loading patterns, minimize product damage, and enhance warehouseefficiency, particularly in high-throughput operations.

Ingredient Handling: Gantry robots are utilized for precisehandling and dispensing of ingredients and additives in food processingfacilities. They accurately measure and dispense ingredients according torecipes, minimizing waste, ensuring consistency, and improving productionefficiency in food preparation and mixing processes.

Quality Inspection: Gantry robots equipped with visionsystems and sensors are employed for quality inspection tasks in the foodindustry. They inspect food products for defects, foreign objects, andcontamination, ensuring compliance with food safety standards and facilitatingearly detection of quality issues.

Sanitary Design: Gantry robots designed for the food industryfeature sanitary designs with smooth, easily cleanable surfaces,corrosion-resistant materials, and IP-rated protection against moisture andcontaminants. This ensures compliance with food safety regulations andminimizes the risk of cross-contamination.

End-of-Line Automation: Gantry robots are integrated intoend-of-line processes for case packing, palletizing, and labeling of packagedfood products. They streamline these processes, reduce labor costs, and improvethroughput, enabling food manufacturers to meet the demands of high-volumeproduction and distribution.

Traceability and Serialization: Gantry robots contribute totraceability and serialization efforts in the food industry by accuratelylabeling, tracking, and tracing individual food products throughout the supplychain. This enhances food safety, facilitates product recalls, and buildsconsumer trust by providing transparency and accountability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gantry Robot System Category

VFD Gantry Series Robot System

Price Range 2500000.00 - 7500000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Industrial

Attributes : Strong, Easy To Operate, Durable, Consume Less Power, Rust Proof

Color : Grey

VFM Gantry Series Robot System

Price Range 2000000.00 - 7500000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Industrial

Color : Grey

2 Axis Gantry Robot

Price 700000 INR / Number

Minimum Order Quantity : 1 Number

Usage : Industrial

Attributes : Strong, Durable, Easy To Operate, Rust Proof

Color : White

DSI - Pick and Place Gantry Robot

Price 900000 INR / Number

Minimum Order Quantity : 1 Number

Usage : Industrial

Attributes : Strong, Durable, Easy To Operate

Color : White

GST : 33AARFD1027H1ZO

|

|

DSI Industrial Automation and Machineries

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry