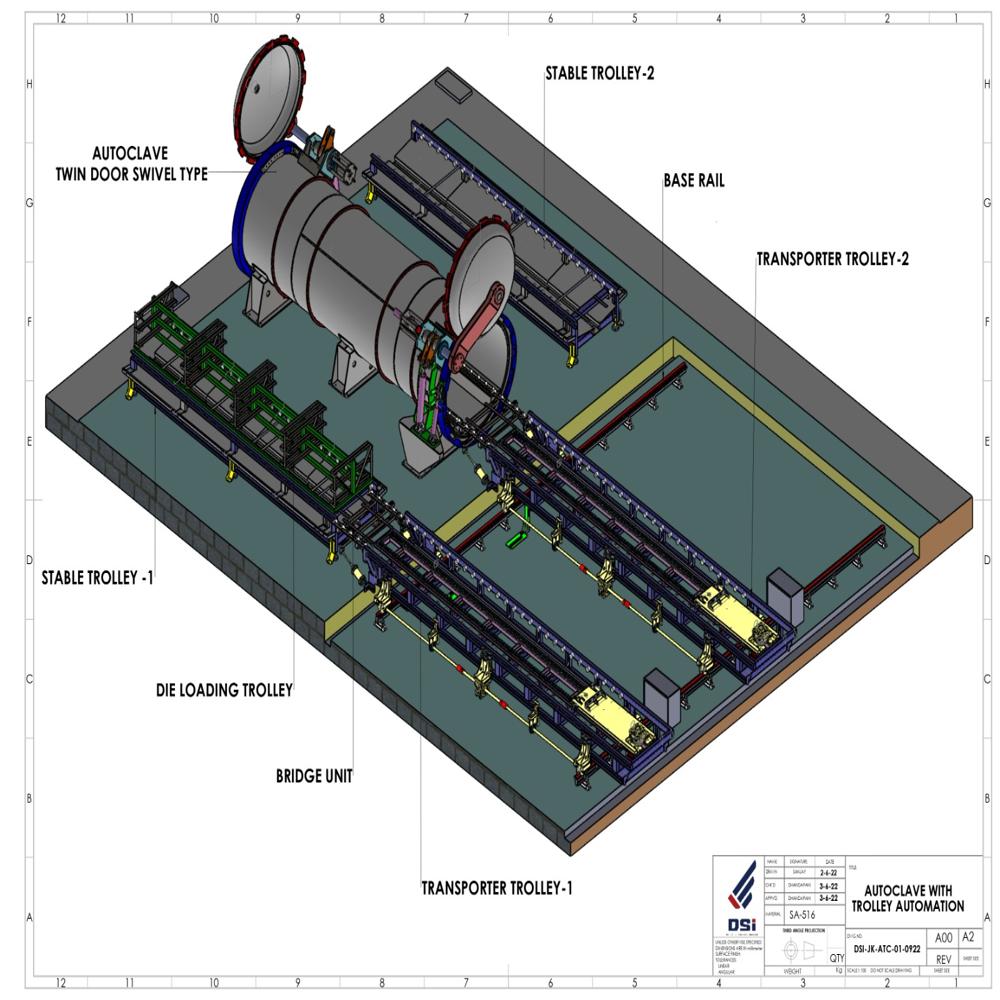

ASRS for Cold Storage system

Price 4750000 INR/ Number

ASRS for Cold Storage system Specification

- Material

- Galvanized Steel / Stainless Steel

- Capacity

- 500 kg to 1500 kg per pallet

- Shape

- Rectangular Modular

- Application

- Cold Storage Automated Warehousing

- Power

- Electric

- Voltage

- 380V / 415V AC

- Storage Height

- Up to 30 meters

- System Type

- Fully Automated Storage & Retrieval System (ASRS)

- Control Interface

- PLC with Remote Monitoring

- Noise Level

- Below 70 dB during operation

- Fire Safety

- Integrated fire detection & prevention

- Travel Speed

- Up to 120 m/min

- Integration

- Compatible with WMS & ERP systems

- Aisle Width

- Minimum 1.5 meters

- Retrieval Accuracy

- ±2 mm

- Operation Mode

- Automatic / Manual override

- Temperature Range

- -30°C to +5°C operation

- Rack Construction

- Insulated and Corrosive Resistant

- Installation Type

- Indoor, Heavy-duty Industrial

- Seismic Compliance

- Designed for high seismic zones

- Maintenance

- Low-maintenance design, easy access

ASRS for Cold Storage system Trade Information

- Minimum Order Quantity

- 1 Number

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 5 Per Year

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About ASRS for Cold Storage system

ASRS (Automated Storage and Retrieval System) for cold storage systems refers to the implementation of automated technologies for the storage and retrieval of goods within temperature-controlled environments, typically below freezing point. Here's how ASRS can be adapted for cold storage systems:

-

Specialized Equipment: ASRS systems for cold storage need to be equipped with specialized materials and components that can withstand low temperatures without compromising performance. This includes conveyor belts, robotic arms, and storage racks designed to function effectively in sub-zero environments.

-

Temperature Control: ASRS systems must integrate seamlessly with the cold storage infrastructure to maintain the required temperature levels throughout the storage and retrieval process. This ensures that perishable goods remain within the prescribed temperature range to prevent spoilage.

-

Inventory Management: ASRS systems incorporate advanced inventory management software that tracks the location and status of goods stored in the cold storage facility. This software enables real-time monitoring of inventory levels, expiration dates, and other relevant metrics to optimize storage space and minimize waste.

-

Automation and Robotics: Cold storage ASRS systems typically utilize automated guided vehicles (AGVs), robotic arms, or cranes to transport goods within the facility. These robots are programmed to navigate the storage environment safely while efficiently retrieving and storing items according to predetermined algorithms.

-

Space Optimization: ASRS systems are designed to maximize storage density within the limited space available in cold storage facilities. By utilizing vertical storage space and implementing compact storage configurations, ASRS helps optimize storage capacity while ensuring easy accessibility to stored goods.

-

Safety Measures: Safety is paramount in cold storage environments due to the extreme temperatures involved. ASRS systems incorporate safety features such as sensors, alarms, and emergency stop mechanisms to prevent accidents and ensure the well-being of personnel working in the facility.

-

Integration with Supply Chain Systems: Cold storage ASRS systems are often integrated with broader supply chain management systems to facilitate seamless coordination of inventory movement, order processing, and distribution. This integration enables end-to-end visibility and control over the flow of goods within the supply chain.

Advanced Cold Storage Performance

Engineered to operate in freezing environments from -30C to +5C, this ASRS maintains reliable functionality for sensitive goods. The insulated and corrosion-resistant construction ensures durability and prolongs system life, while the modular design facilitates adaptability to various warehouse layouts. Operators benefit from low noise levels and a compact aisle requirement, boosting both comfort and storage density.

Seamless Automation & System Integration

The automated system features programmable logic control (PLC) along with both automatic and manual override modes, accommodating diverse operational needs. It seamlessly integrates with warehouse management and enterprise resource planning systems, enabling efficient inventory and order tracking. Remote monitoring allows real-time supervision, making the system both user-friendly and highly efficient.

Unmatched Safety and Reliability

Designed for indoor, heavy-duty industrial settings, the ASRS boasts integrated fire detection and prevention, as well as seismic compliance for high-risk areas. The insulated, galvanized, or stainless steel racks withstand harsh cold and mechanical stress, ensuring consistent operation. Maintenance is streamlined with easy access features, further reducing downtime and operational costs.

FAQ's of ASRS for Cold Storage system:

Q: How does the ASRS for Cold Storage maintain operational efficiency at extremely low temperatures?

A: This system is engineered with insulated, corrosion-resistant racks and tailored components, ensuring reliable automation from -30C to +5C. It sustains high travel speeds and precision even in sub-zero conditions, reducing the risk of temperature-sensitive product compromise.Q: What benefits does the fully automated ASRS offer compared to manual cold storage solutions?

A: A fully automated ASRS increases storage density, improves retrieval accuracy (2 mm), and minimizes labor exposure to cold environments. Automation also enhances inventory management, throughput, and safety, while providing low-maintenance operation and energy-efficient performance.Q: When should this ASRS be considered for a cold storage facility?

A: This system is ideal for facilities requiring high-density storage, reliable operation at extreme temperatures, quick retrieval speeds (up to 120 m/min), and stringent environmental safety standards, especially in high seismic risk zones.Q: Where can the ASRS for Cold Storage be installed?

A: It is specifically designed for indoor, heavy-duty industrial environments, supporting installations across cold storage warehouses, distribution centers, and similar facilities throughout India.Q: What is the process for integrating this ASRS with existing operations?

A: Integration is facilitated via PLC control with compatibility for popular Warehouse Management Systems (WMS) and ERP platforms. The manufacturer supports tailored configuration, remote commissioning, and onsite training to ensure smooth adoption into established workflows.Q: How easy is maintenance for this cold storage ASRS?

A: The system features easy-access components and a low-maintenance design, reducing both downtime and operational disruption. Scheduled servicing and remote diagnostics further streamline upkeep, catering specifically to the demands of cold environments.Q: What are the key safety features included in this ASRS?

A: Safety is ensured with integrated fire detection and prevention systems, seismic compliance for high-risk zones, and noise levels consistently below 70 dB. These features collectively protect both personnel and high-value inventory.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Automated Storage and Retrieval System Category

Automated Storage and Retrieval System Unit Load With WMS Software

Minimum Order Quantity : 1 Unit

Material : Mild steel

Size : Customized

Application : Commercial

Shape : Customized

Automated Storage and Retrieval System for Textile industry

Price 4500000 INR / Number

Minimum Order Quantity : 1 Number

Material : MS

Size : Different Sizes Available

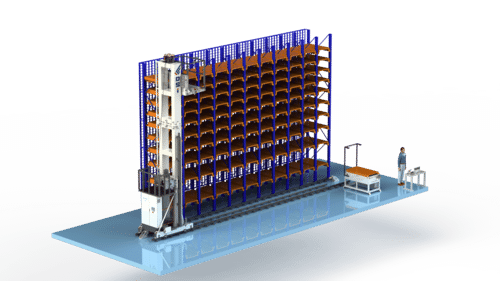

Autoclave with Trolley Automation

Price 1800000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Mild Steel

Size : As per buyer's requirement

Application : Industrial

Shape : Customized

GST : 33AARFD1027H1ZO

|

|

DSI Industrial Automation and Machineries

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry