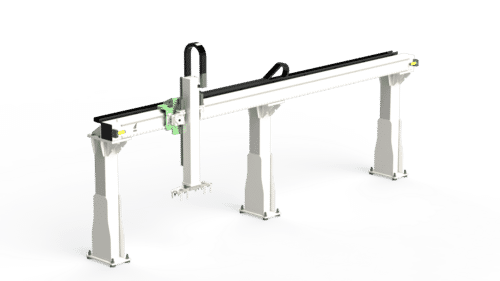

3 Axis Gantry robot for Beverage industry

Price 900000 INR/ Unit

3 Axis Gantry robot for Beverage industry Specification

- Condition

- New

- Size

- Different Sizes Available

- Power Source

- Electric

- Color

- White

- Attributes

- Strong

3 Axis Gantry robot for Beverage industry Trade Information

- Minimum Order Quantity

- 1 Unit

- Delivery Time

- 10-15 Days

- Main Domestic Market

- All India

About 3 Axis Gantry robot for Beverage industry

Gantry robots have become indispensable assets in thebeverages industry, where they streamline production processes, improve efficiency,and ensure product quality and safety. With their precision, speed, andversatility, gantry robots automate critical tasks across different stages ofbeverage production, packaging, and distribution.

In the beverages industry, gantry robots are utilized in thefollowing key applications:

Palletizing and Depalletizing: Gantry robots play a vitalrole in palletizing finished beverage products such as bottles, cans, andcartons, as well as depalletizing raw materials and packaging materials. Theyoptimize pallet loading patterns, stack products efficiently, and ensure stablepallet loads, thereby enhancing warehouse efficiency and reducing manual labor.

Packaging Automation: Gantry robots are employed in variouspackaging processes, including case packing, tray loading, and shrink wrappingof beverage products. They handle product orientation, grouping, and placementwith high precision, ensuring uniformity and consistency in packaging formats.

Bottle Handling: Gantry robots facilitate the handling ofbottles during filling, capping, labeling, and inspection processes in beverageproduction lines. They transport bottles between different stations, positionthem accurately, and ensure smooth flow through the production line, therebyminimizing downtime and maximizing throughput.

Quality Control Inspection: Gantry robots equipped withadvanced vision systems and sensors are utilized for quality control inspectiontasks in the beverages industry. They inspect beverage products for defects,contaminants, and labeling errors, ensuring compliance with quality standardsand regulatory requirements.

Material Handling: Gantry robots are deployed for materialhandling tasks such as transporting ingredients, packaging materials, andfinished products within beverage manufacturing facilities. They optimizematerial flow, minimize handling errors, and improve overall operationalefficiency.

End-of-Line Automation: Gantry robots are integrated intoend-of-line processes for beverage packaging, where they perform tasks such ascase sealing, labeling, and palletizing. They automate these processes, reducemanual labor requirements, and increase production throughput, enablingbeverage manufacturers to meet the demands of high-volume production anddistribution.

Traceability and Serialization: Gantry robots contribute totraceability and serialization efforts in the beverages industry by accuratelylabeling, tracking, and tracing individual beverage products throughout thesupply chain. This enhances product safety, facilitates recalls, and ensurescompliance with regulatory requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gantry Robot System Category

DSI - Pick and Place Gantry Robot

Price 900000 INR / Number

Minimum Order Quantity : 1 Number

Attributes : Strong, Durable, Easy To Operate

Usage : Industrial

Color : White

Condition : New

3 Axis Gantry robot

Price 1000000 INR / Unit

Minimum Order Quantity : 1 Unit

Attributes : Strong, Durable, Easy To Operate, Rust Proof, Consume Less Power

Usage : Industrial

Color : White

Condition : New

3 Axis Gantry robot for Automobile industry

Price 1200000 INR / Number

Minimum Order Quantity : 1 Unit

Attributes : Strong, Durable, Easy To Operate

Usage : Industrial

Color : White

Condition : New

3 axis Gantry Robot For Palletizing

Price 900000 INR / Unit

Minimum Order Quantity : 1 Unit

Attributes : Strong, Durable, Easy To Operate, Rust Proof

Usage : Industrial

Color : White

Condition : New

GST : 33AARFD1027H1ZO

|

|

DSI Industrial Automation and Machineries

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry